We recently completed a concrete countertop for a fire pit in Bedford, VA.

Most people hear “concrete countertops” and they imagine us coming into their home to form & pour concrete right in their kitchen. There are many reasons we like to pour countertops in our shop, but the main reason is that our process is messy.

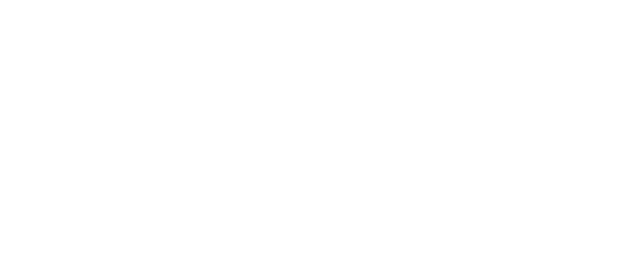

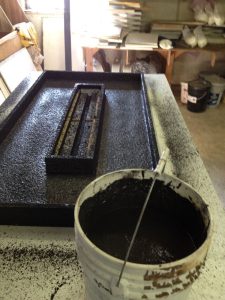

We start by forming the countertops out of a smooth material called melamine. The concrete countertops are formed upside down, so the texture of the melamine is what gives the concrete a flat surface. After the forms are built, we caulk & seal them so that concrete cant leak out between any of the boards.

At this point we are ready to pour the concrete countertops. We start by spraying the forms with a colored concrete grout mix. This spray is what will eventually become the surface of the countertop. Once the surface has been sprayed, we make another batch of concrete that has glass fibers in the mix. This mix is called GFRC. (Glass fiber reinforced concrete). We pour the GFRC mix on top of the sprayed face coat and screed the concrete level to the top of the forms.

Once the concrete has set, we remove the forms and flip the concrete over. Then we wet polish the entire surface with progressively finer grits of diamond impregnated pads. Once we get the concrete polished to the customers desired level of sheen, we seal it to protect it from stains.

Click here for a free tutorial on how we make concrete countertops.

The next day , we delivered the concrete countertop to the job site and buffed it one last time.

I took a few photos as we were building the concrete countertop for the firepit so that you can see exactly how we did it.